-

Keeping your mine site running is our priority

You need high quality, well engineered, cast or fabricated parts that are guaranteed to meet or exceed OEM specifications and you need them fast. We have got you covered with linear deliveries and bulk purchasing options to help manage your changeouts.

-

Quality Management

We are proudly ISO9001 certified which means that we are certified safe, efficient and effective.

-

Reverse Engineering

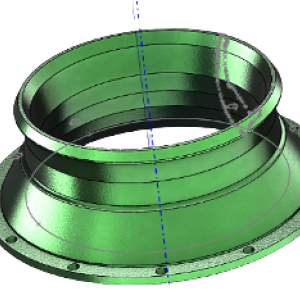

We have the ability to reverse engineer critical solutions to keep your mine site operational. Our linear deliveries and bulk purchasing options allow you to control your supply chain of wear parts and custom cast parts with accuracy and strategy. Let our engineers use the latest in 3D modelling technologies, accurate to within 0.0005” scan, create and certify all your engineering needs.

-

Customised

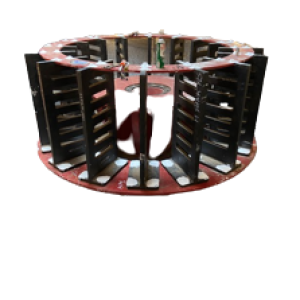

Custom design, engineering and machining of high quality cast parts for the mining industry

- Large selection of alloys tailored specifically to your application requirements

- High Quality Parts certified through rigorous in house testing

- Engineered to meet or exceed OEM specifications

- Excellent customer service and follow up from our highly experienced sales staff

Foothills have been pursuing alloy improvements for over 70 years

We deliver high performance solutions in an industry leading timeframe

Our Solutions Include:

- Linear Deliveries

- Bulk Purchasing Options

- High Quality Products and Service

- Large Alloy Selection

- Superior Casting Methods

- Largest Manganese parts inventory in the industry

- Engineering Capabilities

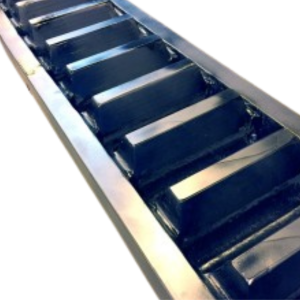

We Manufacture Pipe Spools

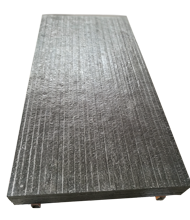

Custom machined pipe spool solutions that last longer and

keep OilSand Mines operating efficiently and profitably

Custom machined pipe spool solutions that last longer and

keep OilSand Mines operating efficiently and profitably

1

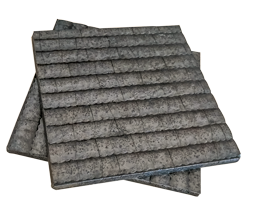

Choose High chrome inserts to replace neoprene or rubber inserts

2

Ask us about our High-Tech Sensors that identify wear inside pipe segments

3

Utilise our Chrome Carbide Overlay Service – lower capital cost & increase the lifetime of pipe sections

Pipe Spools | Centrifugal Cast Pipe Spool Inserts | Flow T Elbow | CCO Spool Overlays

INDUSTRY TESTIMONIAL

Foothills helped develop our High Chrome Pipe Spool inserts in a proprietary 750BHN alloy, which has increased the lifecycle of the pipe exponentially and increased our profit substantially

Manufacturers of High Performance Cast Wear Parts, helping to drive Global Mining cost reductions.